New to Screen Printing

First, a Little Screen Printing History...

Screen printing was a technique first used by the Chinese almost 2000 years ago. Human hair was stretched across a wooden frame to create a screen. Stencils made from leaves were then attached to the screens. This is considered to be the first application of screen printing.

Later, the Japanese adopted the screen printing process and used woven silk to create the mesh and lacquers to make stencils. The use of silk is where screen printing got its alternative name "Silk Screening".

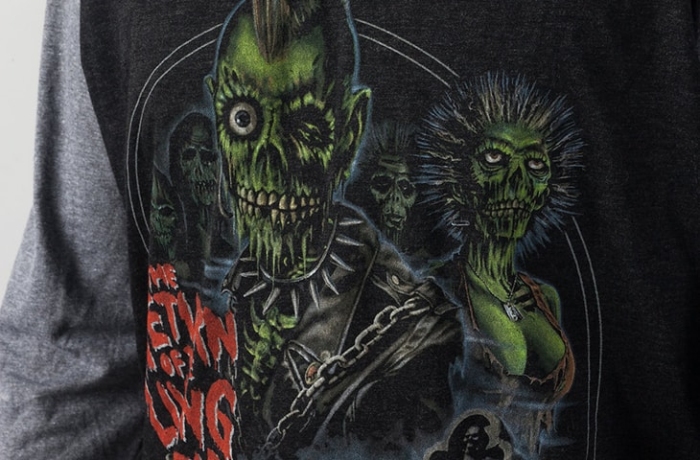

When it comes to apparel printing, screen printing is the industry standard for superior quality. Most graphic tees sold in major retail stores have been screen printed. The process is designed to make garments bold in appearance yet cost effective at the same time.

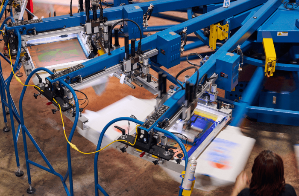

Today, screen printing is accomplished by making a mesh stencil (called a screen) for each color that needs to be printed. Screens must be lined up (or registered) and printed on test sheets to ensure that all of the colors line up correctly. Inks are then pushed through the screens one color at a time onto the apparel. Finally, each piece is run through a large dryer to cure the inks.

Want to know more screen printing information, check out this article we wrote on the screen printing process or this Wikipedia article

Screen printing is designed to be printed in bulk. The printing part of the process is actually the fastest part. All the costs and time are in the setup. This is why the cost per shirt goes down the more you print per design.

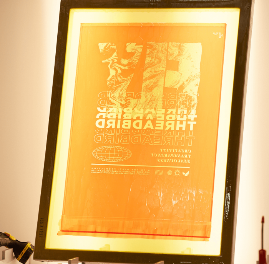

A lot of work goes into getting a shirt ready to print and requires almost every employee at the company. Artwork has to be mocked up and films have to be created. After this, the screens department converts the film into screens. Next, the printers setup the presses to run the shirts. It takes a good bit of time to setup a press to run shirts.

Because of this we cannot print 1 shirt at a time as it would easily cost $150+ to do. The smallest order of shirts we will do is 24 of the same design.

A lot of factors go into the final cost of a screen printed tee. We have tried to make things as simple as possible, starting with providing free screens & setup fees. We also provide our special underbase free of charge. You just need to decide what garment you would like to print on, how many shirts you want of each design and how many ink colors will be in the design.

Check out our Screen Printing Pricing Charts or drop us an email and we can send you a full quote.

Picking out a brand and style can sometimes be the hardest part of the process. There are many different options, catered to different situations and personal preferences. We've attempted to help eliminate some of the confusion on our brands and styles pages to make printing shirts easier.

If you can think of a color, we can print it. The hard part is telling us what the color is. The only true way to do this is by providing us with a PMS color #. To do this you need a Coated Pantone Book. Find the color you want and give us the number next to it.

If you don't know exactly what colors you need, no problem. We will do our best to pick them out for you but cannot guarantee a perfect outcome (this is called "PMS Color Matching"). Every computer monitor is different, so the colors on your screen will look different when displayed on the monitors in our art department.

Your print will only be as good as the artwork you provide. All files need to be at least 300 dpi or vector format & sized to the size it should be printed. Learn more about prepping your artwork files for screen printing.

Most companies charges a screen fee and/or setup fee on top of the printing charge, which can range from $15 to $30 for every color that needs to be printed. That's not how we operate. Our goal is to streamline the process and make you confident in your final product.

At Threadbird, there's nothing "standard" about our standard printing process. We believe that you shouldn't have to pay extra to get a great quality print. We use a special hybrid style of printing, applying a discharge underbase with our special soft inks on top. The outcome is a beautiful, bright, super-soft print (even on dark colored shirts). And they only get softer after you wash the shirts!. We have won multiple awards using this premium screen printing method method and it's all done at no additional charge to you.

(Note: Discharge only works on 100% cotton shirts.)

In order for a print to be perfect you have to print on a smooth, flat surface. Any print that goes over a seam, collar or any other uneven surface will never be perfect because the screens cannot lay flat on the garment. We always recommend staying away from any printing that will go over seams but we will gladly do it at your request.

Note: Threadbird will not accept responsibility or provide refunds for garments that have print errors due to printing over any seam.

"All-Over" printing is accomplished using a process called cut-and-sew, in which the fabric is printed prior to being made into a t-shirt. This is a service that Threadbird does not currently offer. We can print on jumbo screens which are 23.5 inches tall by 17.25 inches wide. This will cover most of the front of a shirt on an adult small not including the sleeves.

Due to the nature of the screen printing process it is very common for a shirt or 2 to be missing from your order. Shirts can get damaged during the printing process or we might get shorted by the vendor. In order to keep prices down, we cannot order extra shirts. Please keep this in mind when ordering (it is never a bad idea to order extras).

We always do our best to get you what you ordered. Whatever you don't receive will be refunded or credited to you.

Want to take your product and your brand to the next level? Let us help you customize! We have all types of different finishing options like Custom Tagging & Bagging.

The Screen Printing Process

Everything You've Always Wanted to Know About Screen Printing But Were Too Afraid to Ask

But really... what IS screenprinting? For us, screenprinting is undoubtedly an art form (note: the hipster undertone there is unintentional, we swear). The attention to detail that goes into the screenprinting process is crucial - and because we understand the importance of that, we know how to deliver superior quality products. There are a lot of moving parts to the screenprinting process that must fit perfectly together in order to achieve the best end result - take it from us, we know a thing or two!

Screenprinting is...

- Not an exact science

- Best for vibrant designs

- Done in bulk

- Manually handled

How Does screenprinting Work?

Ink + screen (mesh stencil) = screenprinting! Luckily, the screen printing process itself has very little limits on what surfaces can be used to print on. Staying on trend is easy-peasy with this screen printing process, considering all of the awesome ink types available that can manipulate the “look” of the final print. Expert printers (enter Threadbird!) understand the relationships between the various inks, shirt materials, and shirt colors - with this knowledge, we’re able to help achieve the look you’re going for.

Screenprinting - Technically Speaking

One screen (mesh stencil) is used for each color to be printed - screens must be lined up (or registered) and printed on test sheets to ensure that all of the colors line up correctly. Inks are then pushed through the screens one color at a time onto the apparel. Finally, each piece is run through a large dryer to cure the inks.

The Benefits of Screenprinting

More than just shirts. Many people think screenprinting is limited to shirts only - this couldn’t be more false! Here’s the lowdown on what can be screen printed - tote bags/purses, jackets, mouse pads, flags, banners, signs, bandanas, and more.

Achieve custom results. You can get the results you want by manipulating the screenprinting process - we strive to guide our customers through the entire order process in an effort to ensure your expectations are met! Need a faded print on a specific shirt? We’ve got you covered. Need to color match the inks to a very specific color you have in mind? Super easy.

Explore different options. Think you’re limited to a plain old cotton shirt for screenprinting? Think again! There are a ton of great synthetic fabrics out there that work great with screenprinting - polyester, silk, viscose, and more.

Screen Printing Templates

T-Shirt Templates

Business Cards

Postcards

8.5" x 11" Brochures

11" x 17" Brochures

Digital Posters

Hang Tag Templates

Buttons

Screen Printed Posters

- 8.5" x 11" Posters

- 9" x 24" Posters

- 11" x 17" Posters

- 12" x 36" Posters

- 18" x 24" Posters

- 24" x 36" Posters

Square Stickers

Circle Stickers

- 2" x 2" Circle

- 2.5" x 2.5" Circle

- 3" x 3" Circle

- 3.5" x 3.5" Circle

- 4" x 4" Circle

- 4.5" x 4.5" Circle

- 5" x 5" Circle

- 5.5" x 5.5" Circle

- 6" x 6" Circle

Rectangle Stickers

- 2.75" x 1.75" Rectangle

- 3" x 2" Rectangle

- 4" x 2" Rectangle

- 5" x 2" Rectangle

- 5" x 3" Rectangle

- 5" x 4" Rectangle

- 6" x 2" Rectangle

- 6" x 4" Rectangle

- 10" x 3" Rectangle

Oval Stickers

Discharge Printing

Discharge printing is the process of bleaching the dye out of the shirt, leaving its natural color showing through (usually a tan color). We can also PMS match discharge ink, however results vary depending on shirt color & brand. The only major downside with the discharge printing process is that you must wash the shirts before they take their "no feel" state. How do we know that - we have been working with discharge inks for over 10 years now!

Examples of Discharge Printing

What is Discharge Printing?

Discharge printing is the process of using water-based inks to bleach the manufacturer’s dye out of a shirt and replacing it with whatever dye color you choose. This kind of discharge screen printing is done with water-based inks that soak into the fabric, instead of just sitting on top of it. Typically this is done with cotton tees that are black, gray or darker in color.

Discharge Printing Advantages

There are a few great advantages to choosing discharge printing for your custom apparel printing.

Softer look and feel. Everybody loves those super soft cotton tees that make groggy Monday mornings just a little less terrible. Custom t-shirts made with discharge printing have a softer look and feel than t-shirts made with plastisol ink.

Lighter weight. Discharge printing is also great for big prints, so you can have that huge design you want, without all the heavy weight. Large print design and plastisol ink don’t mesh very well, especially if you prefer lightweight, airy clothing.

Vibrant colors. Want bright, vibrant colors for your custom t-shirt design? Although discharge printing is typically done with darker materials, you can still get those bright, awesome colors your design needs to pop.

More detail. If your design is super epic and you don’t want to miss out on any of that amazingness, discharge printing will maintain the integrity of all those important details.

So you’re probably reading this thinking, “Wow, this is awesome! But there has to be a downside to discharge printing.” Well, you’re right. The only major downside with the discharge printing process is that you have to wash the shirts before they take their "no feel" state (by “no feel” we mean you won’t be able to feel the ink sitting on top of the fabric of the shirt). Although not all colors will discharge, our design experts at Threadbird can help you determine the best printing method for your custom apparel.

Why Choose Threadbird for Your Discharge Printing?

We’ve been working with discharge inks for over 10 years now and we know the ins and outs of making your design look its best with discharge printing or any other style of printing we offer. Contact us today to place an order or to learn more about discharge printing.

Waterbase Printing

Water-based printing features inks that are soft, breathable and able to soak into the fabric of the garment, rather than sitting on top. When water based screen printing is done correctly, they result in crisp, bright prints that you can't feel to the touch!

When to use Waterbase Printing:

- For super-soft, no-feel prints

- On white or light-colored garments

- On dark-colored garments for a strong faded/vintage look (color of garment impacts the ink)

Can waterbase inks be printed on dark garments?

Absolutely. When waterbase inks are printed on dark garments we typically call this Discharge Printing, since we need an extra element to bleach the original color out of the shirt before printing the super soft waterbase ink. However, we can also print straight Waterbase onto dark garments in order to achieve a faded/vintage effect or a tonal effect.

Examples of Waterbase (Water-Based) Printing:

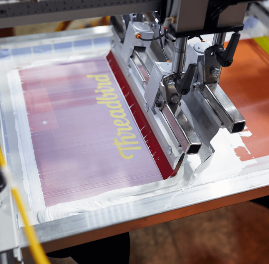

Premium Standard Printing

At Threadbird, there's nothing "standard" about our standard screen printing process. You should not have to pay extra to get great quality apparel printing. We have won multiple awards for our quality with this style of premium screen printing and it's something we offer at no additional charge to you.

Examples of Premium Standard Printing

What exactly is Premium Standard Screen Printing?

We use a special hybrid style of printing in which we use a discharge underbase with our special soft inks on top. This allows us to create a strong print with bright colors while keeping the printing really soft (even on dark colored shirts). And it only gets softer after you wash the shirts!

Are there any fees or restrictions with Premium Standard Printing?

Absolutely no fees! We offer this amazing quality of printing at no charge. Please consider the following restrictions when choosing Premium Standard:

- Only works on 100% Cotton garments (Unless you are trying to achieve a particular effect!). Our Customer Account Specialists can help you determine the best way to print your garments based on your desired outcome.

Landing Page (Sample)

This is a Landing Page Showing Content Blocks

This page has been created as a Sample Page to show all of the available Content Blocks that can be added to a page - with names and descriptions.

Flex card sections can have 3, 4 or 5 cards per row. There are currently four

types of cards. 1. Content Cards = Image and Text. 2. Content Card w/ Button = Image, Text & Button.

3. Vertical Card w/ Icon = Icon, Heading & Text. 4. Card Text Collapsing = FAQ Style Card that Collapses

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

This Flex Card Section is nested inside a Full Container,

which allows us to use the Blue Wave Background.

Flex Cards x4

This Flex Card section is nestled inside a Full Container like the 3x Card.

Custom Pocket Tee

Create a sublimated pocket stitched onto a premium t-shirt.

Production time 3-4 weeks

What is Sublimation?

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Title Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Testing

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Turnaround & Shipping FAQs

When can I expect my order?

| Order Type |

Finishings |

Production |

Shipping Time |

|---|---|---|---|

| Printed Apparel | No | 10-15 Business Days | 1-5 Business Days, depending on shipping destination. Expedited shipping options are available! |

| Printed Apparel | Yes | 15-20 Business Days | 1-5 Business Days, depending on shipping destination. Expedited shipping options are available! |

Standard screen printing turnaround time for production is 7-10 business days (this is for STANDARD ORDERS ONLY). *Please note - orders with any of the following specs may take longer: finishings, higher color counts, multiple print locations, process print, and speciality inks.

What are my shipping options?

If you’d like to expedite your order, alternate shipping options are available on a case-by-case basis. Free order pickup is available at our Orlando, FL headquarters - with this option, you will not be charged for shipping.

*Production time excludes shipping time & is dependent on quick mock approval from the customer.

How will my order be shipped?

Your screen print order will be shipped via FedEx Ground.* Once your order is shipped, we will e-mail you a tracking number - don’t forget to check your spam folder for this one!

*FedEx Ground is used for all orders with standard turnaround time. 2 Day, 3 Day, Overnight & other rush options may be available on a case-by-case basis as determined by your Customer Account Specialist.

How can I check the status of my order?

You can login to your Customer Account for updates on your order anytime. You can also give us a call or send your Customer Account Specialist an e-mail to receive the status of your order! Once your order is shipped, you will also be e-mailed a tracking number.

What can affect/delay order turnaround time?

The following items will be subject to a longer turnaround time past our standard turnaround terms:

- Printed tags

- Hang tags

- Hem tags

- Folding & bagging

- Process prints

- Delayed mock approval

Your order turnaround time will begin once we have all of the following (and not before that!)

- Screenprint-ready artwork as confirmed by your Customer Account Specialist

- Approved mock of your design(s)

- Invoice payment

File Prep for Screen Printing

Prepare Your Art

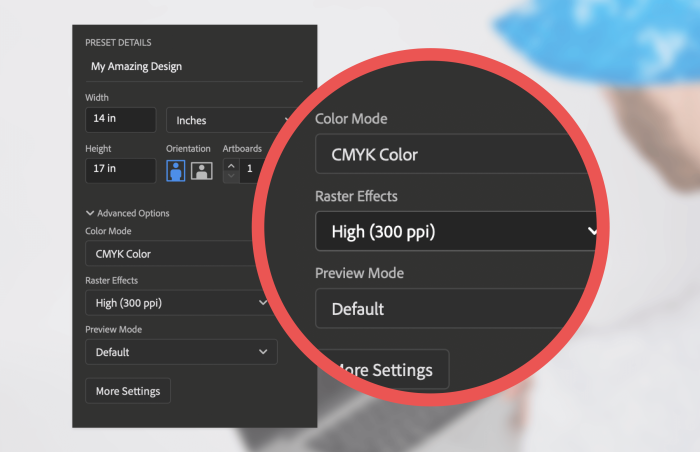

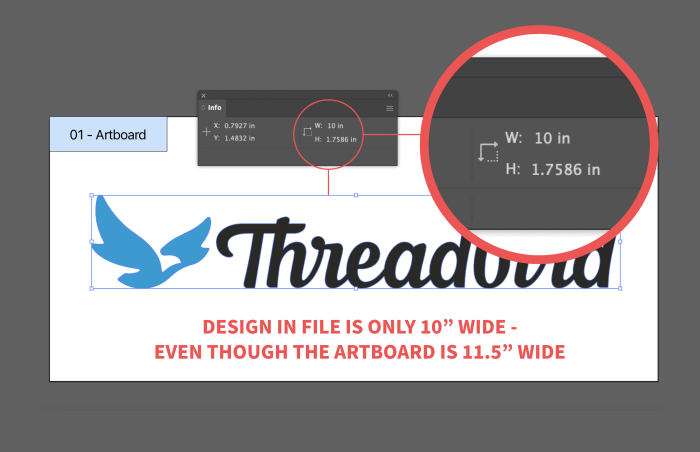

All files must be at least 300 ppi or Vector Format for screen printing. If your file is not 300 ppi, you cannot just increase the resolution of the file. This is called "upsampling" and will result in a blurry image. If you are creating your file in Adobe Illustrator or another Vector-based software, just size your image to the size you want it to print.

Please Note: 3 or more color changes is no longer considered the same design!

Half Tones: Please allow us to halftone the images for you. If we do not control the halftones, we cannot guarantee the quality of the print. We do understand that some designs are complex and will require separation fees, as a client you may be inclined to try to separate or halftone the image yourself to try to keep your cost as low as possible. Unfortunately this does not work. Our computers in the art department are calibrated to set the halftones specifically for the films and screens that we use for printing. Often times if you try to separate or halftone the image yourself it may cause more art charges than you would have originally incurred.

Accepted File Types

We accept the following File Types for Screen Printing:

- Illustrator (.AI)

- Vector (.EPS)

- Photoshop (.PSD)

- JPEG

- TIFF

We prefer .AI or .EPS files first because Vector images can be scaled without affecting quality. We prefer .PSD or .PDF second & .JPG or .TIFF last. Check out our blog 'How to Prep & Quality Check Your Artwork' to learn more about file prep!

Size Your Design

Your screen print logo or design should be sized to the size it should be printed. If you want your print to be 10" wide, please be sure the actual design within the file is 10" wide, not just the background of your design file. Go to the T-Shirt Templates Page, download the appropriate template and place your design on the template to the size you would like it to appear on the shirt.

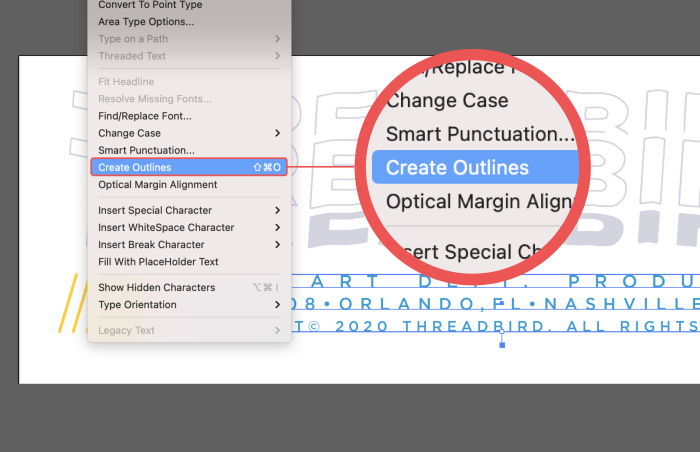

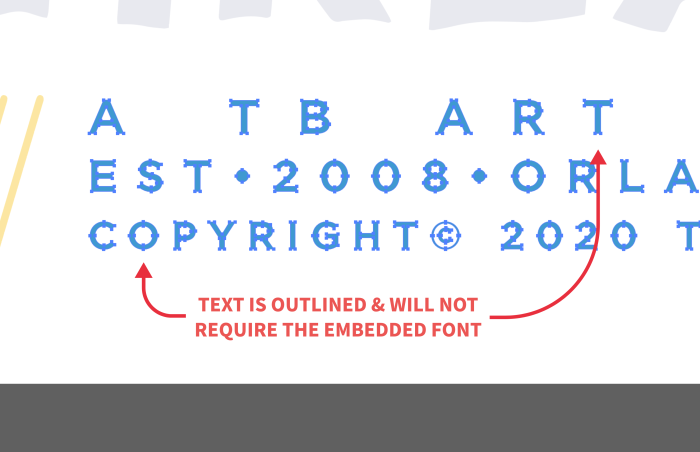

Convert Your Text to Outlines

If you are creating your file in Adobe Illustrator, you will need to choose "Create Outlines" on all your text. This allows us to open the file without requiring the font.

Use Our Templates

Use one of Threadbird's screen print design templates to submit your final design. Go to the Templates Page. (For Apparel Printing Threadbird Templates are not required but recommended.)

Working with Canva Templates

If you don’t have the Adobe programs or you’re looking for some templates to inspire you, Canva can be a helpful place to start. In order to get the best outcome for your print-ready designs, it's super important to know how to set up your Canva template properly.

One beneficial feature of the platform is the built-in design and printing service (for Direct to Garment Printing only) called Smartmockups. Once you have created your design, this tool allows you to visualize how your design will look on a t-shirt. You may need to resize your design to fit the shirt. **It's important to note, some capabilities within Canva require users to have the paid version of Canva. These include:

- Resizing the artboard with your designs. The artboards in Canva are auto set to 14” x 18”.

- Exporting PNG files with a transparent background.

When you're ready to export your designs, hit the ‘Share’ button > Downloads > PDF Print. Doing this will export the file with the necessary DPI resolution of 300 required for printing. For text based designs, we also recommend saving them as a PDF file.

Threadbird Screen Sizes

- Standard Screens - 14" x 17"

- Jumbo Screens - 18" x 23"

Printed/Sewn In Tag Information

It is required by the US Government that the following information be included in all garments:

- Size

- % of Material

- Country of Origin (for the garment, not your brand)

- Care Instructions

Please feel free to use one of our custom tag templates to help create your tag files: Download Tag Template here.

These are non-negotiable. We cannot list "Printed in the US" or "Processed in the US" instead of listing what country the shirt is manufactured in, it *must* have the country information on the garment. If you are unaware of the information needed for the shirts you are ordering, please leave your tag files editable and add place holders for the information. When you submit your artwork, please submit the editable tag file (PSD or AI) as well as the fonts used to create the tag. The fonts are very important as we cannot edit fonts we don't have.

To find out more about these rules, please visit this resource called: Threading Your Way Through the Labeling Requirements Under the Textile and Wool Acts

Picking PMS Colors

We will provide free pantone color matching for your garments when your orders are submitted. However, there is an issue with pantone matching, and that is that not every color looks the same on every monitor. A certain red on your screen may appear to be a different red on ours. There is no universal color calibration for computers. It is always best to try to supply your own pantone colors if possible. The best way to do this, and the most accurate way, is to purchase a Pantone Plus Series Solid Coated Formula Guide. This can be purchased as part of the set (Coated and Uncoated) through Amazon. The reason why it's best to buy the book, once again, is the pantone guide on your version of photoshop is still using your color calibration, and will not necessarily be accurate.

Max Imprints

Please note that not all shirts will be sewn exactly the same; these dimensions are to be used for reference as a "safe" zone to avoid printing on any seams or edges. Be sure to check the specific product page for "Size Specs" specific to that garment. NOTE: Any print that goes over a seam can result in imperfections in the print. (Which can be very cool-looking, if you're into that.)

Unisex/Mens

- X-Small - 12" x 20"

- Small - 13" x 22"

- Medium - 15" x 23"

- Large - 17" x 24"

Womens/Juniors

- Small - 11" x 18"

- Medium - 12" x 19"

- Large - 12" x 20"

- X-Large - 12" x 21"

Youth

- Small - 13" x 13"

- Medium - 13" x 16"

- Large - 14" x 19"