One Design, Printed Three Different Ways

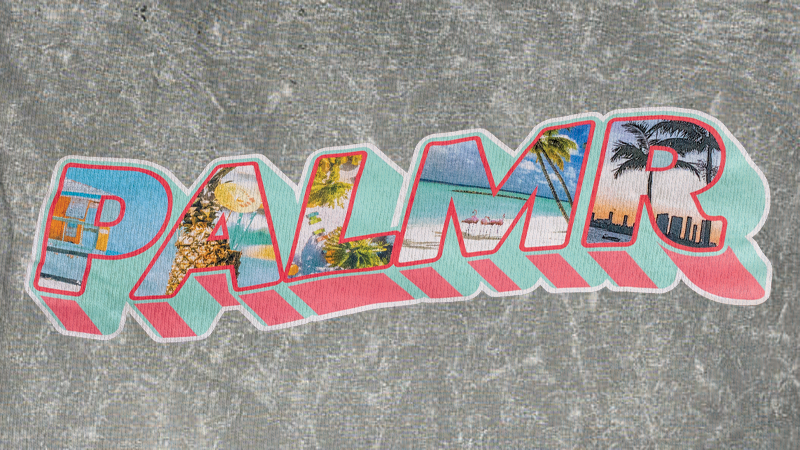

For context, we printed this Palmr Style design on US Apparel’s mineral-washed tee (YJY-4138).

Screen Printing

Not to brag about ourselves, but when it comes to screen printing we are pretty dang good at it. Compared to most other screen printing shops, Threadbird has mastered how to achieve premium quality prints and intricate details on a wide range of products.

Screen printing is not only our bread and butter but it’s one of our major strengths as a company. With this particular full-color design from Palmr Style, we wanted to capture the high-level of detail and color from the design. To do so, we kicked off this printing experiment by using our speciality printing method known as a Process (Simulated) Printing to recreate the design. Boy oh boy were we impressed with the print outcome!

The results:

The amount of photorealistic detail we were able to replicate was just incredible! Using eleven screens, we blended the unique spot colors from the design to create this vibrant print. Although this method requires more production setup time compared to standard Screen printing, Process Printing shines because it allows greater printing coverage and produces an ultra-soft print.

Our Rating:

Level of Detail: 7

Printing Coverage (Color Saturation): 10/10

Feel of Print: 10/ 10

Strengths:

- Captures intricate design details

- Ultra-soft print

- Printing Coverage & Ink Vibrancy

Weaknesses:

- Production Setup (Time & Cost)

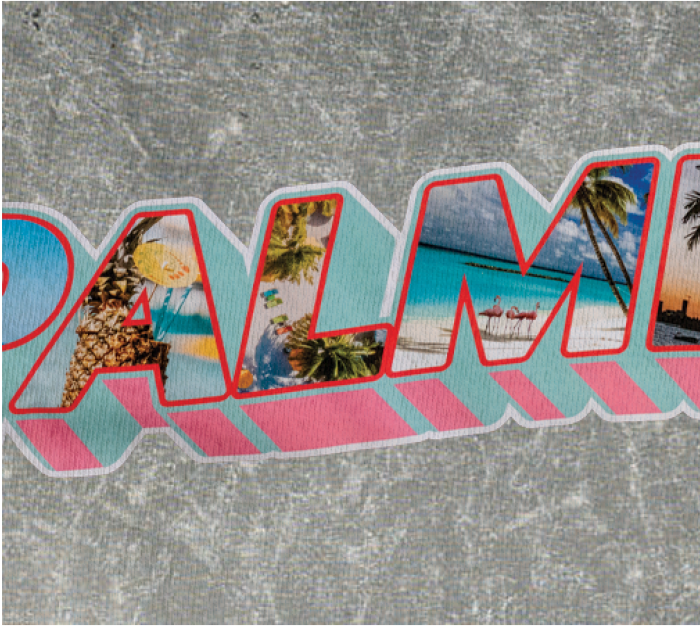

Direct to Garment (DTG)

Direct to Garment isn’t a method that we offer, due to the level of quality that it produces in comparison to screen printing. However for the purpose of this experiment, we wanted to explore how DTG printing compares to screen printing and direct to film printing. What did we find?

The results:

One advantage of DTG is that it allows for printing designs with an unlimited number of colors. This was a noticeable difference between the print outcome compared to DTF and Screenprinting, as you can see in a few areas such as the color vibrancy of the water in the bubble letter M in the printed design. In terms of the print detail, we didn’t notice a significant difference between the print outcome between screen printing and DTG. One noticeable disadvantage of printing with DTG is the amount of print coverage it allows for on garments.

Although DTG is excellent in replicating photorealistic designs, it isn’t optimal for printing designs with solid colors. As you can see in the image below, the color outlines of the Palmr text aren’t nearly as vibrant or accurate in color compared to the screen printed print.

Our Rating:

Level of Detail: 8

Printing Coverage (Color Saturation): 5

Feel of Print: 10/ 10

Strengths:

- Unlimited ink colors

- Capturing photorealistic details

Weaknesses:

- Print Coverage

- Quality & vibrancy of print fades over time

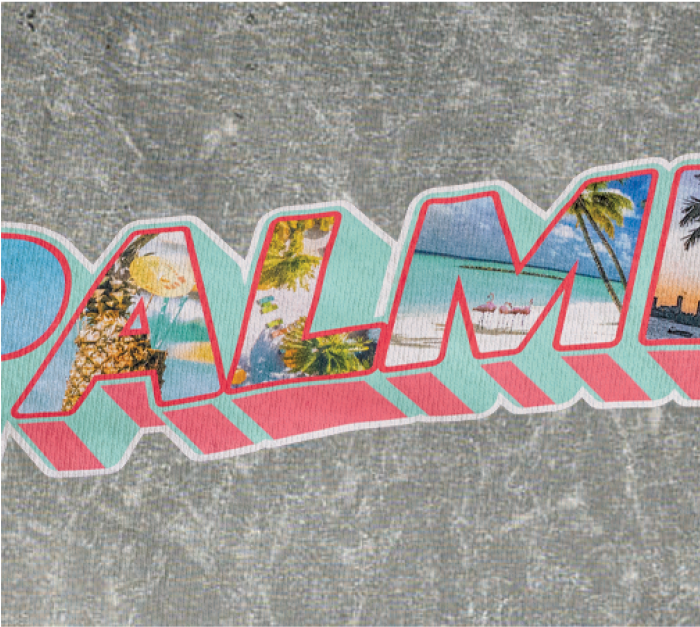

Direct-to-Film (DTF) Transfer

This printing technique is a common choice for printing artwork with a lot of color and design complexity. With this in mind, we were curious to see how DTF transfer method would compare to the print outcome of DTG and Process Printing.

Right off the bat, we noticed how accurately the print captured the little details within the Palmr design. Not only were the details replicated accurately, but they were also very crisp and precise! Unlike DTG, Direct-to-film transfer offers excellent print coverage, in that the entire print is solid and vibrant in color.

Our Rating:

Level of Detail: 10/10

Printing Coverage (Color Saturation): 10/10

Feel of Print: 6

Strengths:

- Captures photorealistic details

- Print Coverage

- Ideal for print small quantities

Weaknesses:

- Heavier look and feel to the print

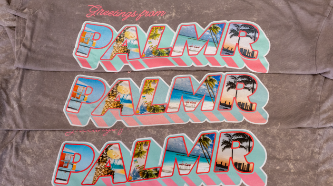

Which method is the top contender?

In testing and assessing the three different printing methods, we have several takeaways about their varying advantages and disadvantages. Let’s break it down.

DTG vs DTF

For overall quality and design compatibility, Direct-to-film Transfers takes the cake. In comparison to the DTG print, DTF’s print is consistently bright in color and the details within the design are also consistent. Plus the quality of the DTF print is superior, and doesn’t fade with every wash.

Direct-to-film Transfer prints often produce a shiny effect on the print, along with almost a plastic look and feel to it. With this in mind, our Threadbird team went the extra mile to mute the glossy effect by adding a secret ingredient when creating this print.

Process Screen Printing vs DTF

After evaluating the two prints, we came to the conclusion that these methods share a lot of similarities in terms of the print outcomes they produce. Perhaps we are a bit biased or old school, but Screen Printing continues to be the outstanding winner that checks all of the most important boxes (quality, vibrancy, texture).

The biggest difference we found in comparing the two printed shirts is that the screen-printed design feels extremely soft and almost has a ‘no-touch’ lightweight feel, whereas the DTF print has a glossy-like finish and a plastic feel. The Direct-to-film Transfer print almost looks too realistic, like a photograph with a glossy shine, versus the process-printed design, which looks like it’s embedded into the t-shirt. Most printers don’t go the next step to attempt to mute the glossy-finish, which is why Threadbird’s DTF method is superior in quality. Threadbird’s Full-color Process Printing can accomplish an impressive level of detail, color, and smoothness that is tough to beat!

When comparing the two methods from a pure cost and speed point of view, Process screen printing is ideal for printing garments in bulk, whereas Direct-to-film Transfer is a better method for printing small quantities, such as 50 shirts.

Screen-Printed T-shirt design is from Palmr Style’s Greeting which you can check out here.

Overall, this printing experiment was very fun and beneficial, allowing us to compare and contrast the three decoration methods. Choosing the best method to recreate your designs can be tricky with all of the different decoration options and ink types that we offer. We fully understand this, which is why our Threadbird team is here to offer recommendations and tips to guide you along the way in your creative journey. Get in touch with us to share your ideas, and our Customer Specialist will connect with you to get started!