Understanding Discharge & Waterbase Printing

Customers frequently ask us about the discharge printing process or water-based printing and why it works on some garments but not others. There’s a lot of information floating around promising that discharge will or will not work, but oftentimes the information lacks insight about the effectiveness or limitations of the ink.

You may already know that discharge ink is primarily used on 100% cotton garments. The ZFS interacts only with Cotton. It does not interact with Polyester or any other materials. To achieve an even color across your print, 100% cotton will create the best results for discharge prints. However, this does not mean that 100% cotton is the only material that you can use with discharge inks.

In the photo above, the 100% cotton shirt in the middle has a very even and consistent white color, while the tri-blend (50% Cotton, 25% Polyester, 25% Rayon) on the left shows the heathering of the garment through the ink and the 50% Cotton/50% Polyester on the right has a very muted mid-range grey print. Results can be somewhat inconsistent and aren’t guaranteed to have an even texture depending on how the knit in the shirt is blended. If the knit is inconsistent (patches of cotton or poly and not even heather) the print will look inconsistent. This is not something that printers can account for, nor does it really qualify as a misprint, it’s just the nature of the beast when using these inks.

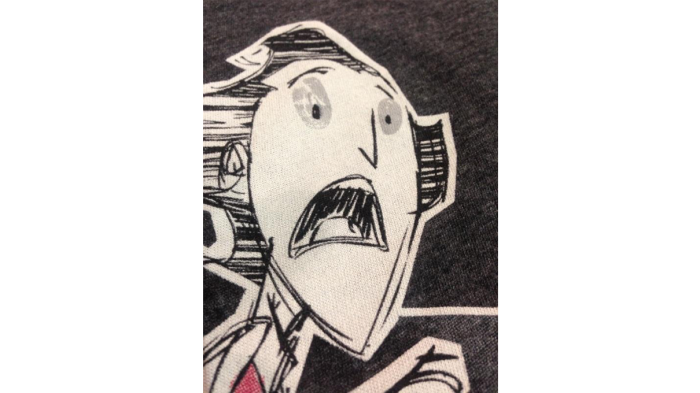

Now that you’ve committed all of these things to memory, let’s throw another wrench in the system when using discharge and heathered 50/50 material. Some manufacturers blend their garments so that the white “heathering” of the shirt is polyester and the colored portion of the garment is cotton, garnering a better discharge effect. This is a great chance to do something out of the ordinary that usually cannot be accomplished. However, not all heathered 50/50’s discharge well, and it’s largely a case-by-case scenario. If you have a project that you think would be a suitable option for using discharge on a 50/50, just ask us and we’ll be happy to look into it for you. Below is a picture of a print using 4 colors, the white is discharge, the grey, black, and red are waterbase.

The Question: “When is it ok to use discharge on a tri-blend or a 50/50?”.

The Answer: “Only when you’ve done your research and you know what is best for your project or brand.”

We hope you have learned something after reading this post. If you have any questions please reach out to us. We would love to answer any questions you may have to make sure that you get the best results possible.

[email protected] / (407) 545-6506